Progress 2024

Dear JP843 Supporters,

Typhoon Legacy is excited to announce that we will soon be starting the assembly of Hawker Typhoon JP843’s cockpit section. Construction for this area is the cumulation of approximately 7 years of research, reverse engineering, CAD design, and material acquisitions.

The cockpit structure is the centre of the aircraft to which every main component is attached; starting construction of this section will first require the manufacture the main spar fittings. With the complexity of these parts, we have had to outsource the machine work to a company with specialized equipment. Costs for this process on all eight fittings will be $45,000 in Canadian funds, and we need your help.

The necessary material has been purchased and delivered, and we have made a down payment of $8000 to get started; but we need your help to raise the remaining funds so that we can start assembly this spring.

I sincerely thank all our supporters who have helped in the past, please help us with this fundraising goal to create the first airworthy Hawker Typhoon cockpit section since the end of the Second World War!

There are many great donation gifts, including large format prints of Typhoon JP843 artwork by noted aviation illustrator, David Bathe. More details in the next pages.

Donations can be made through our webpage using the donate button below. Please feel free to contact us directly if you would prefer to contribute through other means.

Donation Tiers / Gifts

There will be a special printing of 50 numbered and signed David Bathe Typhoon JP843 prints produced to help raise the funds needed to build JP843’s cockpit.

This image represents JP843 as she looked when delivered to 609 Squadron RAF in early June of 1944. Unparalleled effort has been applied to ensuring the accuracy of this image, right down to rivet rows, dirt, and damaged paint. Nose to tail this image measures 95cm in length, so you are sure to not miss any detail!

To provide the best return for your donation, we have broken the rewards into seven tiers which are listed below.

Tier 1: The First donation of $10,000 or more Canadian dollars.

Gone!

The gift offered for this generous donation is print #1 of 50; it will be made to the first donation of this sum received. Signed by artist David Bathe, and includes the opportunity to have your name (or that of someone of your choosing) permanently marked on the inside of JP843’s airworthy port side cockpit panel. It also includes your name listed on our website supporter page, and your name in the video credits for our spar fitting production videos!

Tier 2: A donation of $5,000 or more Canadian dollars.

The gifts offered for a generous donation in this tier are signed print #’s 2 through 10 signed by artist David Bathe and includes the opportunity to have your name (or that of someone of your choosing) permanently marked on the inside of JP843’s airworthy port side cockpit panel. It also includes your name listed on our website supporter page, and your name in the video credits for our spar fitting production videos!

Tier 3: A donation of $1,500 or more Canadian dollars.

The gifts offered for a generous donation in this tier are signed print #’s 11 through 50 signed by artist David Bathe. It also includes your name listed on our website supporter page, and your name in the video credits for our spar fitting production videos!

Tier 4: A donation of $750 or more Canadian dollars.

Sold out!! November 14 2024

A non-numbered, signed print is offered for a generous donation in this tier. It also includes your name listed on our website supporter page, and your name in the video credits for our spar fitting production videos!

Tier 5: A donation of $250 or more Canadian dollars.

Sold out!! November 14 2024

A non-numbered print is offered for a generous donation in this tier. It also includes your name listed on our website supporter page, and your name in the video credits for our spar fitting production videos.

Tier 6: A donation of $100 or more Canadian dollars.

Recognition offered for a generous donation in this tier are your name listed on our website supporter page, and your name in the video credits for our spar fitting production videos.

Tier 7: A donation of $1 or more Canadian dollars.

Recognition offered for a generous donation in this tier are your name listed on our website supporter page.

Machine Work Details

With JP843’s forward monocoque section expected to be complete in spring of 2024, our plan is to shift our efforts to the cockpit section, starting with the 8 spar fittings.

There are eight spar fittings in total, six of these start off as 175lb steel blanks, and two start off as 225lb steel blanks. When all eight parts are complete, they weigh less than 20lbs each.

The process for these parts will be:

1) Deliver our materials to the machine shop (complete),

2) Complete rough machining (authorized, deposit made),

3) Heat treatment of rough-cut machine parts,

4) Finish machine work (to final high tolerance),

5) Cadmium plating.

6) Installation on fixture and begin cockpit assembly.

There are three primary complexities in machining these parts:

1) Holding the material for machining (both turning and milling operations) for rough machining and finish machining; this requires several special fixtures to be made.

2) The deep internal bore with a spherical end requires special vibration dampened tooling with a very long reach and unique cutter profiles.

3) There are very tight linear and angular tolerances for the wing spar lugs and rear engine mount locations.

Forward upper main spar fitting and rear engine mount.

The fittings require extensive machine work both internally and externally.

Work on the spar fittings started many years ago with the reverse engineering of our surviving examples (at no cost) by our sponsor E3D Technology. With the geometry captured, the digital models were used as the basis of our cockpit design and component verification process. The CAD work on this section alone represents many thousands of hours.

Extensive resources have been provided by our sponsors to get us this far (E3D Technology Stephen Ecklin PEng).

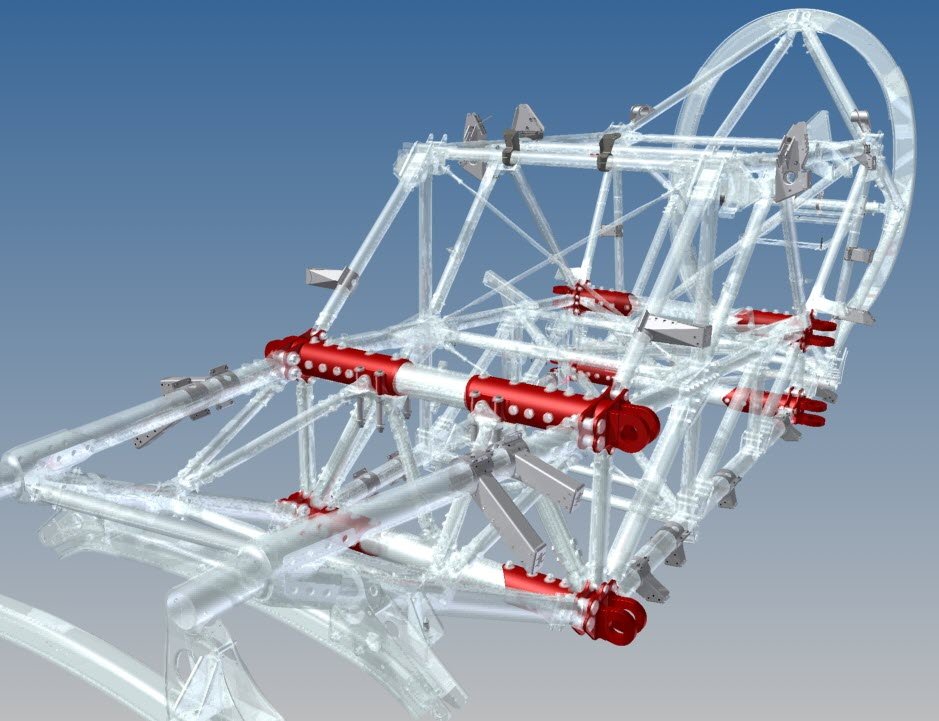

The Typhoon’s cockpit assembly fully designed in CAD after years of work.

While CAD development was progressing, the materials for the fittings and most of the tubular structure were acquired and the fixture table for the cockpit was built. Coinciding with this work, new equipment was purchased and connected in the shop which will allow Typhoon Legacy to produce all special Hawker hardware for the assembly. Our sponsor, Pyrotek Aerospace has even donated a small hydraulic press brake which will allow us to bend the stainless-steel plates used in the cockpit!

We have now secured the materials, tooling and have completed our CAD design work for more than 6200 individual parts required for the construction of the cockpit section, our last major hurdle is to acquire the funding for machine work, can you help us reach our goal?

Donations can be made through this webpage using the “Donate” tab at the top of the page. Please feel free to contact me directly if you would prefer to contribute through other means.

Sincerely,

Ian Slater